-

Volumes 96-107 (2025)

-

Volume 105

-

Volume 104

-

Volume 103

Pages 1-314 (August 2025)

-

Volume 102

Pages 1-276 (July 2025)

-

Volume 101

Pages 1-166 (June 2025)

-

Volume 100

Pages 1-256 (May 2025)

-

Volume 99

Pages 1-242 (April 2025)

-

Volume 98

Pages 1-288 (March 2025)

-

Volume 97

Pages 1-256 (February 2025)

-

Volume 96

Pages 1-340 (January 2025)

-

Volume 105

-

Volumes 84-95 (2024)

-

Volume 95

Pages 1-392 (December 2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 95

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

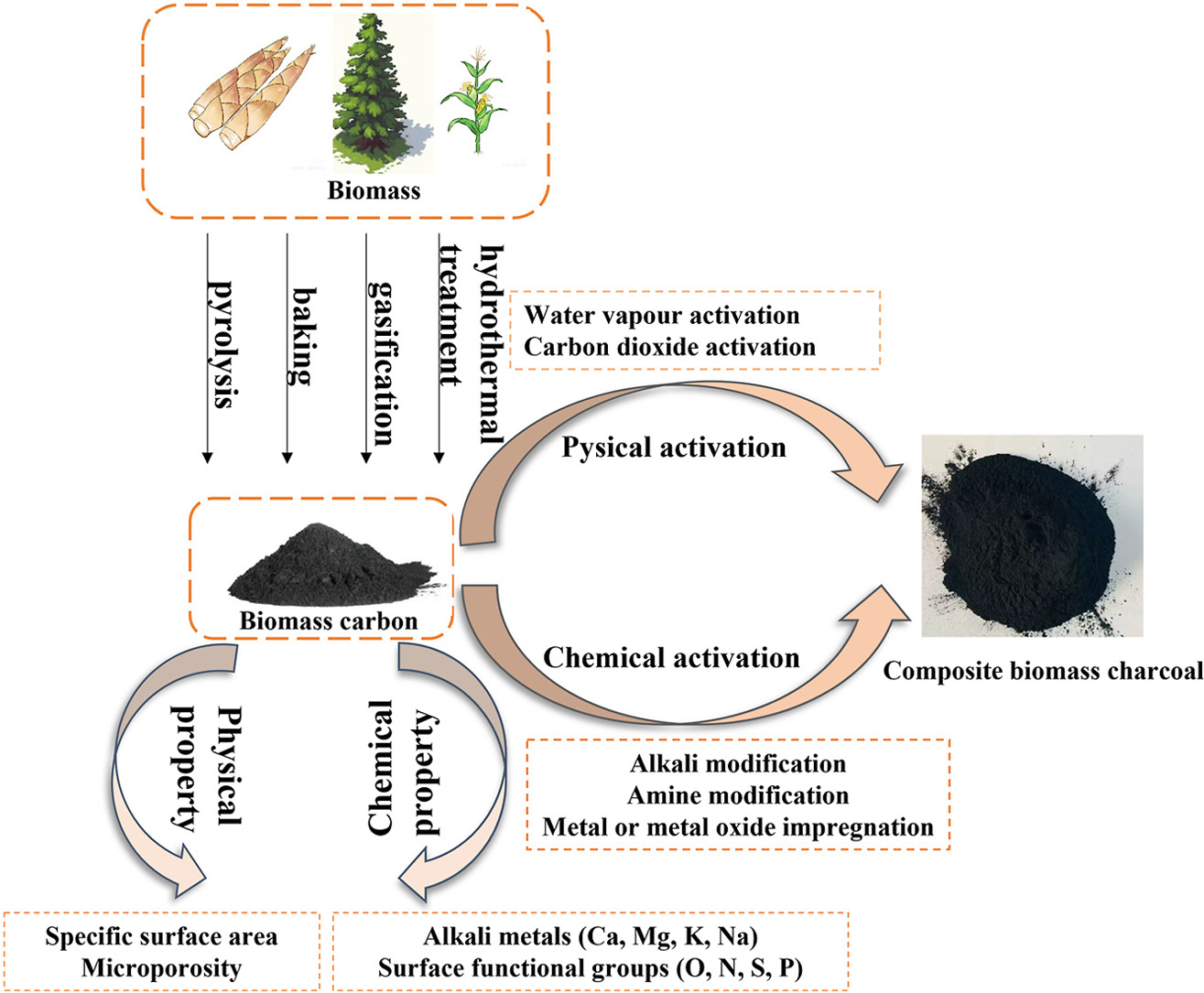

• Sources, physicochemical properties, preparation, and modification of biomass-based CO2 adsorbents are reviewed.

• Surface alkali metals and N/S-containing functional groups enhance biomass char alkalinity and CO2 affinity.

• Physical activation (CO2, steam) and chemical modification (KOH, amine grafting, metal oxide impregnation) boost adsorption capacity.

• Future research should focus on in-situ mechanisms, heteroatom co-doping, and scalable production.

Excessive CO2 emissions pose a severe environmental threat, driving interest in carbon capture technologies. Biomass-derived activated carbon (BAC) emerges as a promising adsorbent due to its renewable feedstocks, cost-effectiveness, and tunable properties. This review comprehensively analyzes recent advances in BAC for CO2 capture. Key findings indicate that agricultural/forestry wastes are optimal feedstocks, while alkali/alkaline earth metals and N/S-containing functional groups enhance surface alkalinity and CO2 affinity. Pyrolysis is identified as the preferred preparation method for optimizing pore structure. Physical activation (CO2, steam) and chemical modification (KOH/NaOH, amine grafting, metal oxide impregnation) significantly improve porosity and adsorption capacity. Notably, N-doping increases CO2 uptake by 31.6–55.2 %, and microporous volume (0.59–0.71 cm3/g) is critical for performance. However, challenges include high energy consumption during KOH activation, feedstock variability impacting consistency (>22 % ash content differences), competitive adsorption from flue gas impurities (>30 % capacity loss), and metal leaching risks. Future research should prioritize in-situ mechanistic studies, heteroatom co-doping, and scalable production techniques to advance industrial deployment.