-

Volumes 96-107 (2025)

-

Volume 105

-

Volume 104

-

Volume 103

Pages 1-314 (August 2025)

-

Volume 102

Pages 1-276 (July 2025)

-

Volume 101

Pages 1-166 (June 2025)

-

Volume 100

Pages 1-256 (May 2025)

-

Volume 99

Pages 1-242 (April 2025)

-

Volume 98

Pages 1-288 (March 2025)

-

Volume 97

Pages 1-256 (February 2025)

-

Volume 96

Pages 1-340 (January 2025)

-

Volume 105

-

Volumes 84-95 (2024)

-

Volume 95

Pages 1-392 (December 2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 95

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

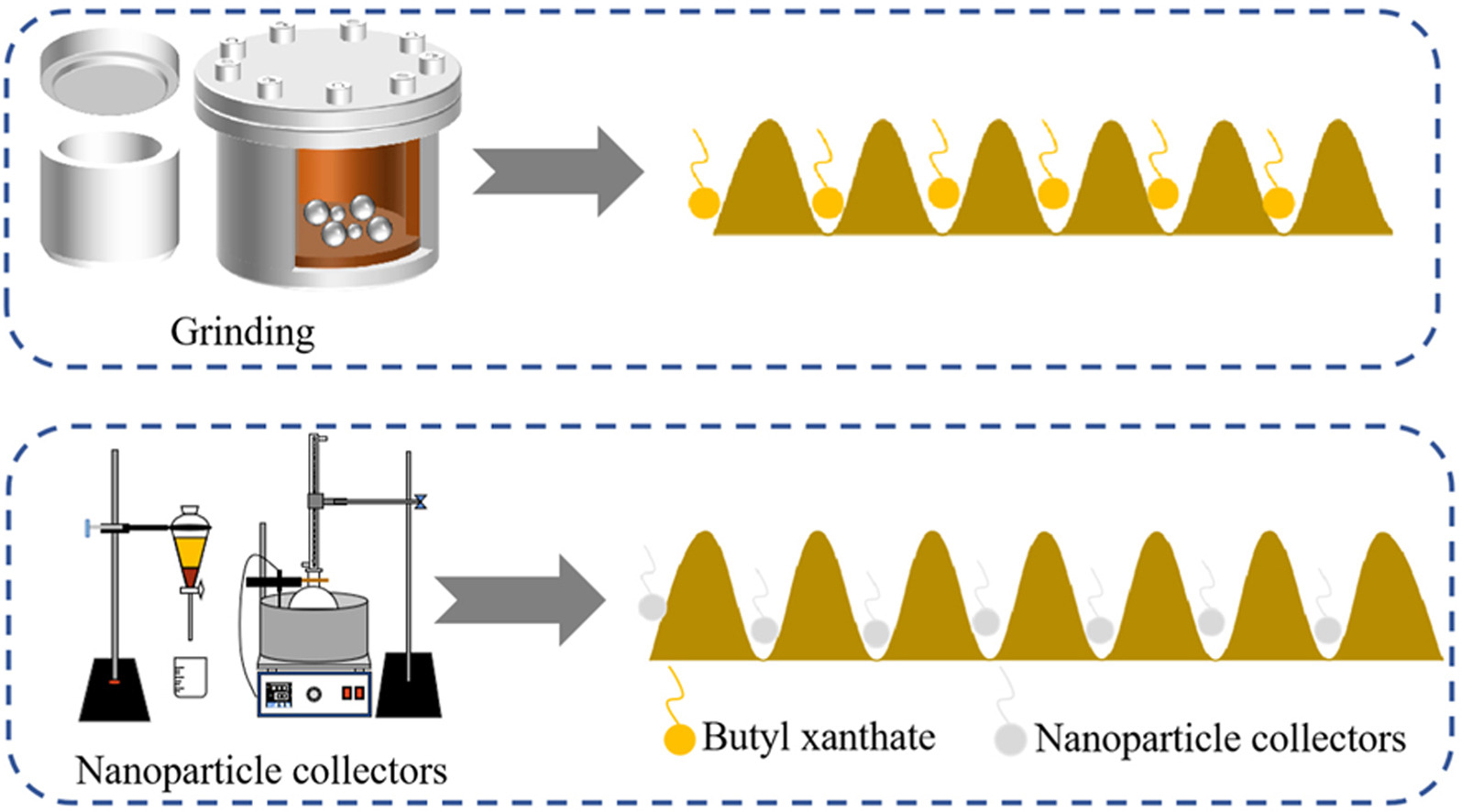

• Surface roughness of chalcopyrite was modified through grinding and nanoparticle collector treatment.

• Nanoparticle collectors synthesized via emulsion polymerization enhanced surface roughness of chalcopyrite.

• Impact of surface roughness on mineral hydrophobicity was validated through experiments and simulations.

Copper, a critical strategic metal primarily from chalcopyrite, is widely used. However, a large amount of chalcopyrite is not effectively recovered resulting from its surface characteristics due to its fine size. This study introduced the use of surface roughness (SR) as a core indicator to evaluate chalcopyrite's flotation performance. Two modification methods including mechanical activation (grinding) and nanoparticle collectors (NPCs) modification were systematically investigated. Grinding enhanced SR from 1.274 to 3.593, improved yield from 55.14 % to 63.21 %, and increased hydrophobicity, as demonstrated by the rise in contact angle from 55.74° to 68.38°. NPCs demonstrated superior performance, with SR reaching 4.987, contact angle up to 90.75°, and yield as high as 91.45 %. The results demonstrated that physical modification (grinding) improved flotability through roughness enhancement, while NPCs offered an optimal solution for chalcopyrite flotation by combining the advantages of increased SR with strong collector interaction. Molecular dynamics simulations revealed the following diffusion coefficient order: CTAB (cetyltrimethylammonium bromide)-NPC > SDS (sodium dodecyl sulfate)-NPC > PEG (polyethylene glycol)-NPC > BX (butyl xanthate) > no collector. This trend demonstrated that higher water molecule mobility corresponded to reduced surface-water binding and enhanced chalcopyrite hydrophobicity induced by collector adsorption. These findings provide valuable insights for optimizing copper mineral processing, particularly for fine chalcopyrite resources.