-

Volumes 96-107 (2025)

-

Volume 105

-

Volume 104

-

Volume 103

Pages 1-314 (August 2025)

-

Volume 102

Pages 1-276 (July 2025)

-

Volume 101

Pages 1-166 (June 2025)

-

Volume 100

Pages 1-256 (May 2025)

-

Volume 99

Pages 1-242 (April 2025)

-

Volume 98

Pages 1-288 (March 2025)

-

Volume 97

Pages 1-256 (February 2025)

-

Volume 96

Pages 1-340 (January 2025)

-

Volume 105

-

Volumes 84-95 (2024)

-

Volume 95

Pages 1-392 (December 2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 95

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

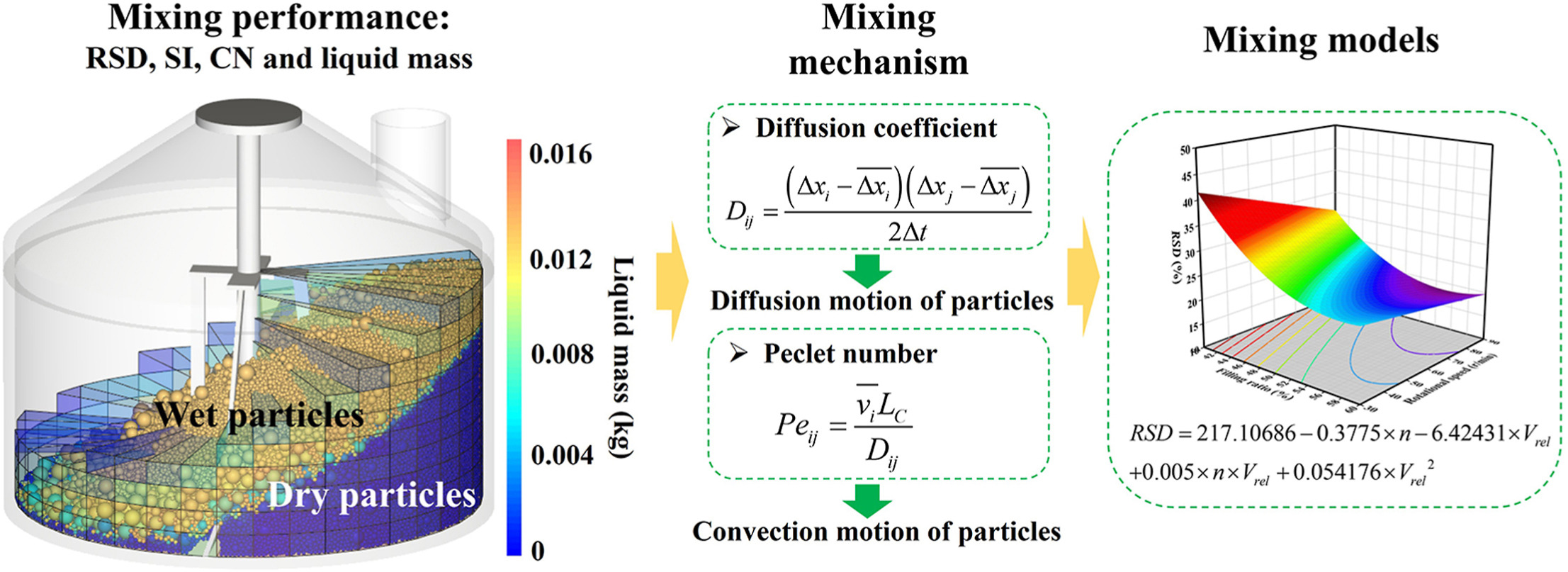

• Impacts of moisture content,process parameters,and inclined angle on mixing performance were analyzed.

• Mixing mechanism i.e. predominance of forced convection in the mixing system persists was revealed.

• Empirical models for RSD,CN,and SI were developed which demonstrated predictive capability for mixing indices.

• Liquid bridge model was adopted to describe moisture transfer mechanism during mixing.

Wet and sticky bulk materials exhibit poor flowability during the mixing process, which prevents adequate contact between dry and wet particles. This results in uneven moisture distribution and deterioration in the mixing system. To address these issues, the mixing process of viscous concrete was focused on a vertical blender. A comprehensive investigation into mixing mechanisms and particles flow patterns were conducted using the discrete element method (DEM). The accuracy of the contact parameters in DEM was calibrated through repose angle and validated by torques tested in a custom-built mixing platform. And then, the effects of moisture content, filling level, rotational speed, and inclined angle were systematically investigated with respect to key mixing metrics: the relative standard deviation (RSD), coordination number (CN), segregation index (SI) of wet particles, as well as liquid mass. The results indicated that when the moisture content is 8 %, filling level is 50 %, and rotational speed is more than 60 rpm, the CN and mixing efficiency are acceptable, and the RSD and SI are low, thereby improving the mixing quality. The convective motion was revealed as the dominant flow regime through statistical quantification of diffusion coefficients and Peclet numbers. Finally, Box-Behnken Design was employed to develop quadratic polynomial models for RSD, CN, and SI, which demonstrated strong accuracy in predicting mixing performance and enabled systematic optimization of critical process parameters.