- Volumes 108-119 (2025)

-

Volumes 96-107 (2025)

-

Volume 107

Pages 1-376 (December 2025)

-

Volume 106

Pages 1-336 (November 2025)

-

Volume 105

Pages 1-356 (October 2025)

-

Volume 104

Pages 1-332 (September 2025)

-

Volume 103

Pages 1-314 (August 2025)

-

Volume 102

Pages 1-276 (July 2025)

-

Volume 101

Pages 1-166 (June 2025)

-

Volume 100

Pages 1-256 (May 2025)

-

Volume 99

Pages 1-242 (April 2025)

-

Volume 98

Pages 1-288 (March 2025)

-

Volume 97

Pages 1-256 (February 2025)

-

Volume 96

Pages 1-340 (January 2025)

-

Volume 107

-

Volumes 84-95 (2024)

-

Volume 95

Pages 1-392 (December 2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 95

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

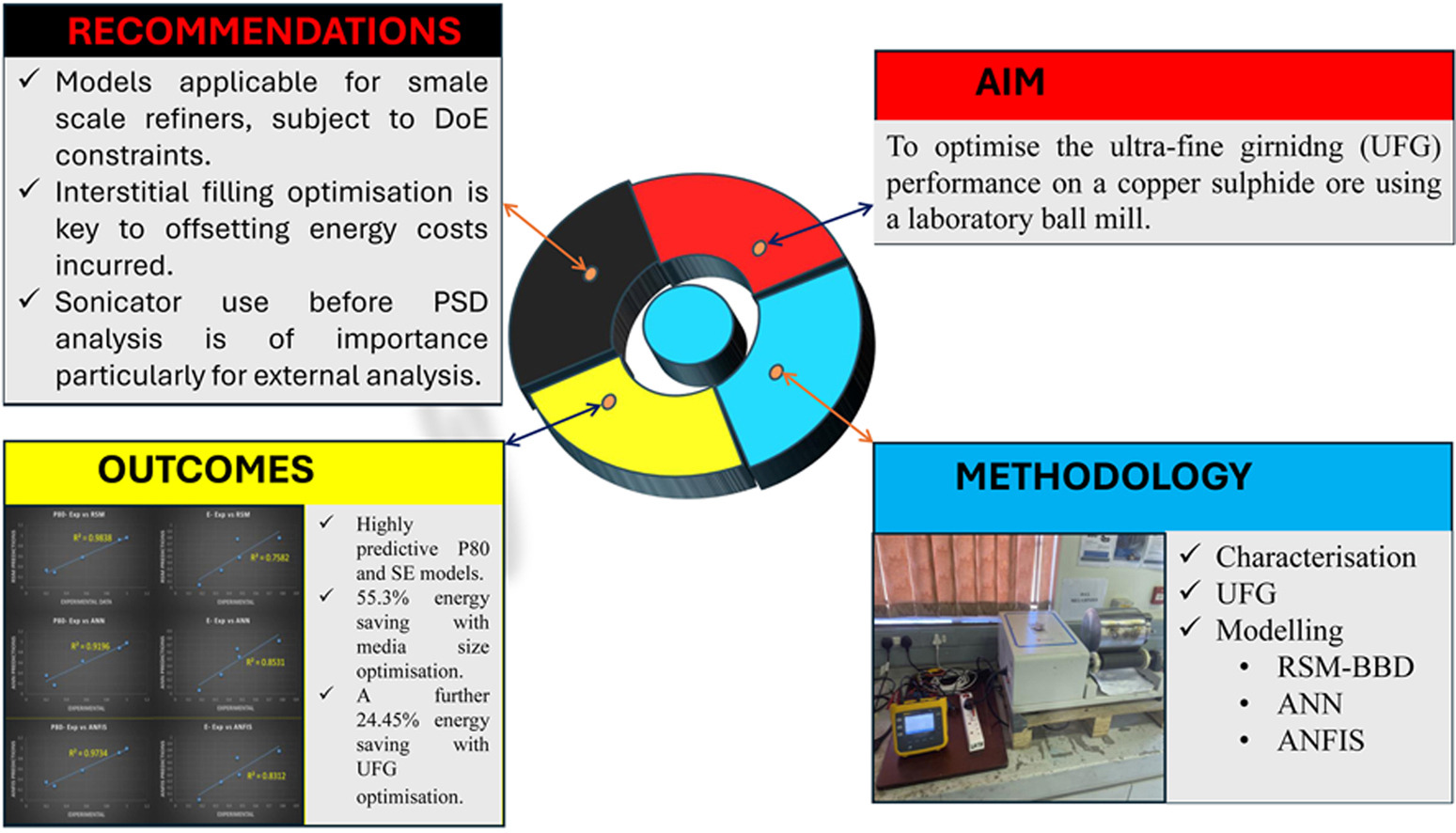

• Hybrid modelling was applied for optimization of ultra-fine grinding (UFG) of a low-grade copper sulphide ore.

• Media filling ratio bears more influence on ultra-fine grinding,compared to the rest.

• Shift from coarse to fine grinding media led to a 55.3 % energy saving.

• Optimization of grinding extent led to a further 24.45 % energy cost saving.

• Higher predictive fidelity and robust transferable model development realized through hybrid modelling.

As the demand for base metals continues to increase, the shift to beneficiating low-grade ores and secondary sources has been steadily increasing over the past decades. This study aimed at optimizing the beneficiation of low-grade copper sulphide ores by applying ultra-fine grinding to mechanically activate its mineral grain surfaces. As an energy intense process, this study sought to streamline the manner in which the milling media particle size impacts the operating conditions, for fine-tuning the process milling efficiency (P80), and its specific energy consumption (SE). The intrinsic interaction behaviors of the operating conditions;milling speed,milling time and grinding media filling ratio,were uncovered through a hybrid modelling technique involving the response surface methodology,artificial neural network (ANN) and artificial-neuro-fuzzy-inference-system (ANFIS) approaches. Through this methodology,it was revealed that the baseline process parameter of dependence,to the rest in this study was the media filling ratio (%). At lower media filling ratios, it was noted that basically the milling speed did not bear much influence on the process performance, however, an inverse impact to the process performance was observed with increasing media filling ratio. For milling time, a direct proportionality was observed between it and media filling ratio, and its proportionality constant could be finely tuned as per set conditions. Optimization study led to adoption of the optimum conditions of media filling ratio, milling time and milling speed of 60 %, 1 h and 106 revolutions per minute (RPM) respectively. Upon optimizing the grinding extent to P80 of 20 μm, a 24.45 % SE conservation was realized, basing on the traditional 10 μm of the Activox process. Validation of the hybrid models using a different sulphide ore drew the superiority of the ANFIS model for P80 predictions, and that of ANN for SE predictions. This study addressed the need, particularly of small-scale miners, to effectively conduct mechanical activation without necessarily incurring expenditure on new milling equipment.