- Volumes 108-119 (2025)

-

Volumes 96-107 (2025)

-

Volume 107

Pages 1-376 (December 2025)

-

Volume 106

Pages 1-336 (November 2025)

-

Volume 105

Pages 1-356 (October 2025)

-

Volume 104

Pages 1-332 (September 2025)

-

Volume 103

Pages 1-314 (August 2025)

-

Volume 102

Pages 1-276 (July 2025)

-

Volume 101

Pages 1-166 (June 2025)

-

Volume 100

Pages 1-256 (May 2025)

-

Volume 99

Pages 1-242 (April 2025)

-

Volume 98

Pages 1-288 (March 2025)

-

Volume 97

Pages 1-256 (February 2025)

-

Volume 96

Pages 1-340 (January 2025)

-

Volume 107

-

Volumes 84-95 (2024)

-

Volume 95

Pages 1-392 (December 2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 95

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

• Thermodynamic parameters of crystallization were derived and calculated through model fitting.

• A kinetic metastable zone prediction model was established based on nucleation theory.

• Anti-Caking performance of SrCl2·6H2O particles was significantly enhanced.

• This work provides a theoretical guidance for practical applications through crystallization theory.

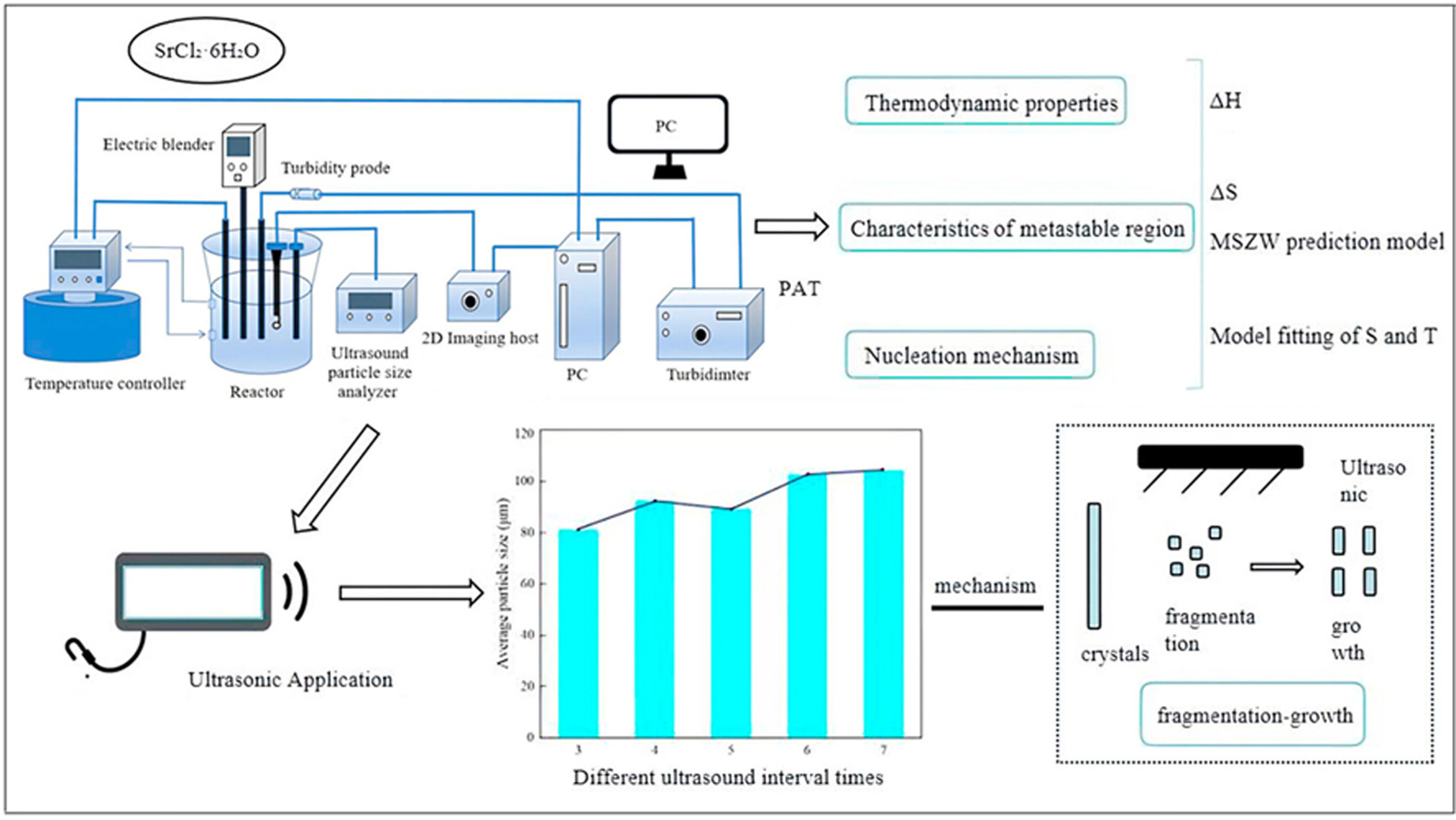

Crystallization remains a fundamental separation and purification technique in chemical manufacturing. A comprehensive understanding of aqueous solution thermodynamics, metastable zone width (MSZW), and nucleation mechanisms is essential for optimizing crystallization processes, defining operational control parameters, and enabling subsequent crystal morphology control. This study systematically investigates the crystallization behavior of SrCl2·6H2O through in situ monitoring using process analytical technology (PAT). Key parameters, including MSZW, thermodynamic properties (solubility, supersaturation), and nucleation kinetics, were quantitatively determined to develop a predictive process model. To address the critical industrial challenge of product agglomeration arising from poor particle morphology, which complicates storage, transportation, and downstream processing while compromising product quality and increasing operational costs, an ultrasonic regulation strategy was implemented under optimized crystallization conditions. Post-treatment with optimized ultrasonic parameters yielded a marked reduction in particle aspect ratio, substantial improvement in dispersion, and a clear morphological transition from rod-like to granular crystals. This transformation significantly enhanced anti-agglomeration performance, thereby increasing product value. The regulatory mechanism of ultrasound is attributed to the "fragmentation-growth" mechanism, where ultrasonic cavitation induces controlled particle fragmentation followed by directional growth.