- Volumes 108-119 (2025)

-

Volumes 96-107 (2025)

-

Volume 107

Pages 1-376 (December 2025)

-

Volume 106

Pages 1-336 (November 2025)

-

Volume 105

Pages 1-356 (October 2025)

-

Volume 104

Pages 1-332 (September 2025)

-

Volume 103

Pages 1-314 (August 2025)

-

Volume 102

Pages 1-276 (July 2025)

-

Volume 101

Pages 1-166 (June 2025)

-

Volume 100

Pages 1-256 (May 2025)

-

Volume 99

Pages 1-242 (April 2025)

-

Volume 98

Pages 1-288 (March 2025)

-

Volume 97

Pages 1-256 (February 2025)

-

Volume 96

Pages 1-340 (January 2025)

-

Volume 107

-

Volumes 84-95 (2024)

-

Volume 95

Pages 1-392 (December 2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 95

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

• A dynamic cell size method is proposed to improve computational efficiency.

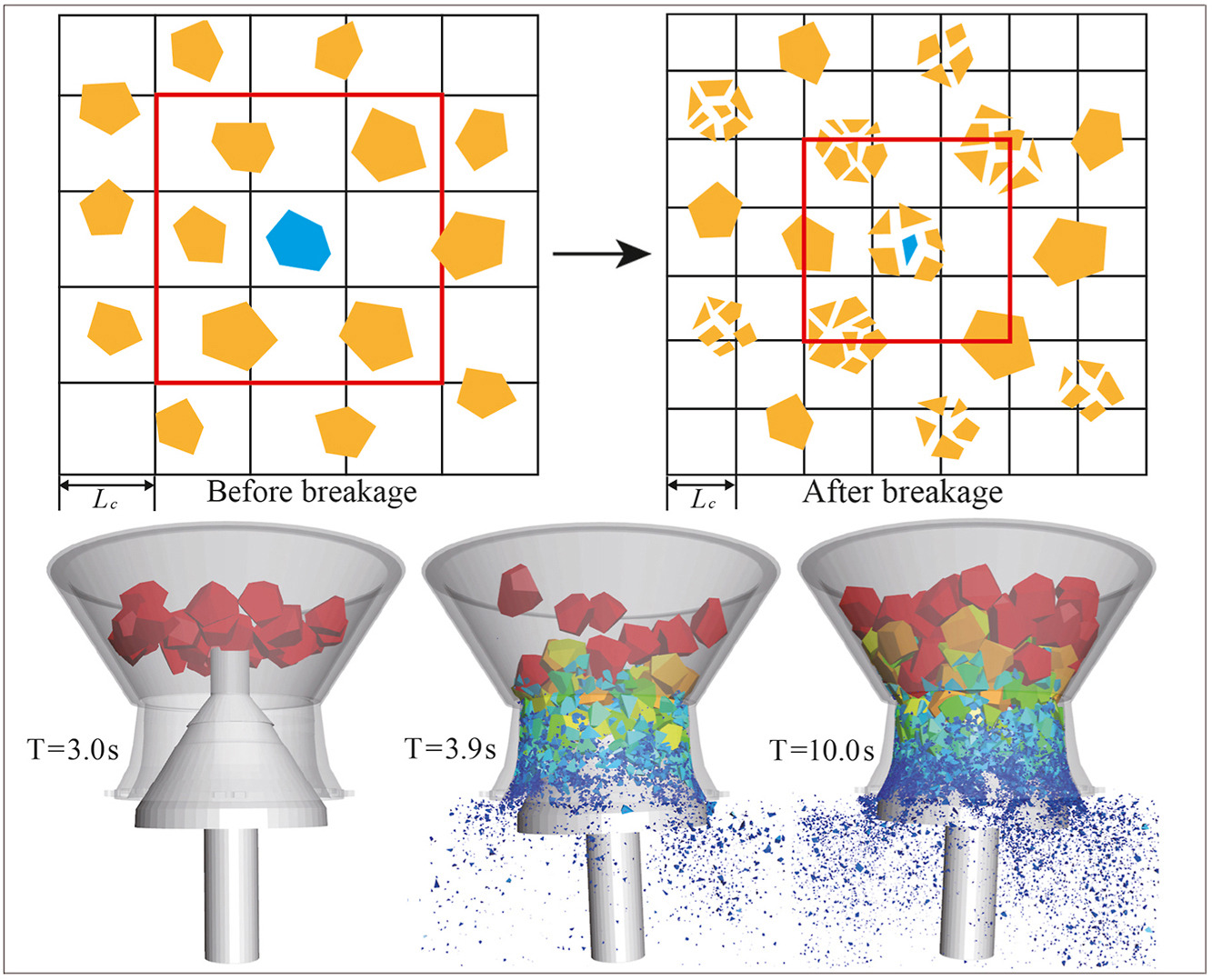

• Simulations of the breakage process in a cone crusher are conducted.

• Efficiency of the breakage simulation is highly improved by this new method.

• Accuracy of the breakage simulation is not influenced by the new method.

The discrete element method (DEM) has become a powerful tool to investigate the breakage process, which has drawn increasing attention in recent years. The process of particle breakage can be regarded as the reduction of the particle size, which results in the explosive growth of particle number, making the computation inefficient. Contact detection is a major process in DEM simulation. The cell size is a crucial parameter for contact detection and has a great influence on computational efficiency. The static cell size method is usually employed, and the size will be set before the simulation according to the particle size. Since the particle size changes during the breakage simulation, the static cell size method is no longer proper. As a result, a dynamic cell size method is proposed in this study. Two parameters are critical in this method that are key to the computational efficiency, including the number of neighbor particles retrieved for a specific particle (Np) and the number of search cells retrieved during the process of finding all neighbor particles (Nc). By integrating this new method, the cell size is supposed to be adjusted according to the ratio of Np to Nc to achieve a high efficiency of contact detection. By comparing the computational time of the same simulation case, the dynamic cell size method achieves substantial computational time reduction for equivalent simulation scenarios, and the efficiency under different cell sizes is recorded to validate the cell size in the subsequent test case.