- Volumes 108-119 (2025)

-

Volumes 96-107 (2025)

-

Volume 107

Pages 1-376 (December 2025)

-

Volume 106

Pages 1-336 (November 2025)

-

Volume 105

Pages 1-356 (October 2025)

-

Volume 104

Pages 1-332 (September 2025)

-

Volume 103

Pages 1-314 (August 2025)

-

Volume 102

Pages 1-276 (July 2025)

-

Volume 101

Pages 1-166 (June 2025)

-

Volume 100

Pages 1-256 (May 2025)

-

Volume 99

Pages 1-242 (April 2025)

-

Volume 98

Pages 1-288 (March 2025)

-

Volume 97

Pages 1-256 (February 2025)

-

Volume 96

Pages 1-340 (January 2025)

-

Volume 107

-

Volumes 84-95 (2024)

-

Volume 95

Pages 1-392 (December 2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 95

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

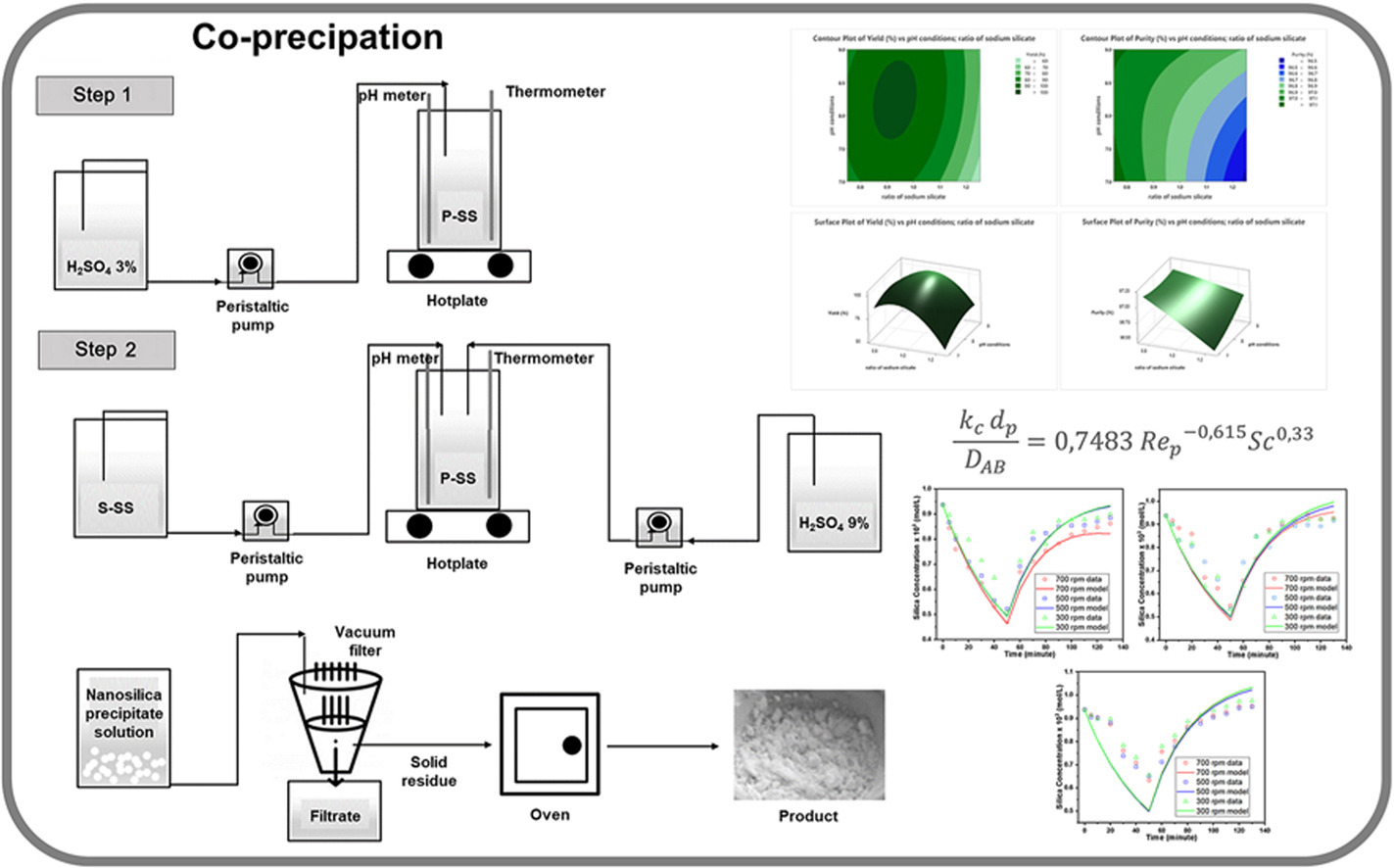

• Optimized co-precipitation yields high-purity silica nanoparticles from geothermal sludge.

• Process maximizes yield (100 %) and purity (97 %) while minimizing reagent use and complexity.

• Nanoparticles are amorphous, nanosized (10–100 nm), and suitable for industrial applications.

• Converts waste sludge (>80 % SiO2) into nanomaterials with ∼60–80 % higher market value.

• RSM–CCD modeling ensures process predictability, reproducibility, and sustainability.

Silica nanoparticles play a vital role in a range of industries, including agriculture, pharmaceuticals, biomedicine, ceramics, and advanced materials. However, conventional synthesis methods typically rely on expensive and environmentally burdensome chemical precursors. This study explores the hypothesis that geothermal sludge, a by-product of geothermal power plants, can serve as a sustainable and efficient source for producing high-purity silica nanoparticles through a simplified synthesis approach. The process involves three key purification stages—water washing, acid leaching, and conversion to sodium silicate—followed by co-precipitation to obtain the final silica product. To optimize the synthesis, experimental conditions were statistically evaluated using response surface methodology to identify the effect of pH and sodium silicate ratio on the silica yield. The highest yield (100 %) and purity (97.03 %) were achieved under neutral pH conditions and a sodium silicate ratio of 1:1 by volume. Material characterization was conducted using elemental analysis, X-ray diffraction, and electron microscopy to confirm the structural and morphological properties. In addition, kinetic modeling revealed the influence of agitation speed and temperature on silica precipitation dynamics, and a dimensionless correlation was developed to quantify the mass transfer coefficient during the process. The findings demonstrate a promising and more sustainable pathway for silica nanoparticle production using industrial waste as feedstock. While direct financial metrics were not assessed, the use of readily available by-products and simplified process conditions suggest potential for economic advantages, meriting further techno-economic evaluation in future work.