- Volumes 108-119 (2025)

-

Volumes 96-107 (2025)

-

Volume 107

Pages 1-376 (December 2025)

-

Volume 106

Pages 1-336 (November 2025)

-

Volume 105

Pages 1-356 (October 2025)

-

Volume 104

Pages 1-332 (September 2025)

-

Volume 103

Pages 1-314 (August 2025)

-

Volume 102

Pages 1-276 (July 2025)

-

Volume 101

Pages 1-166 (June 2025)

-

Volume 100

Pages 1-256 (May 2025)

-

Volume 99

Pages 1-242 (April 2025)

-

Volume 98

Pages 1-288 (March 2025)

-

Volume 97

Pages 1-256 (February 2025)

-

Volume 96

Pages 1-340 (January 2025)

-

Volume 107

-

Volumes 84-95 (2024)

-

Volume 95

Pages 1-392 (December 2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 95

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

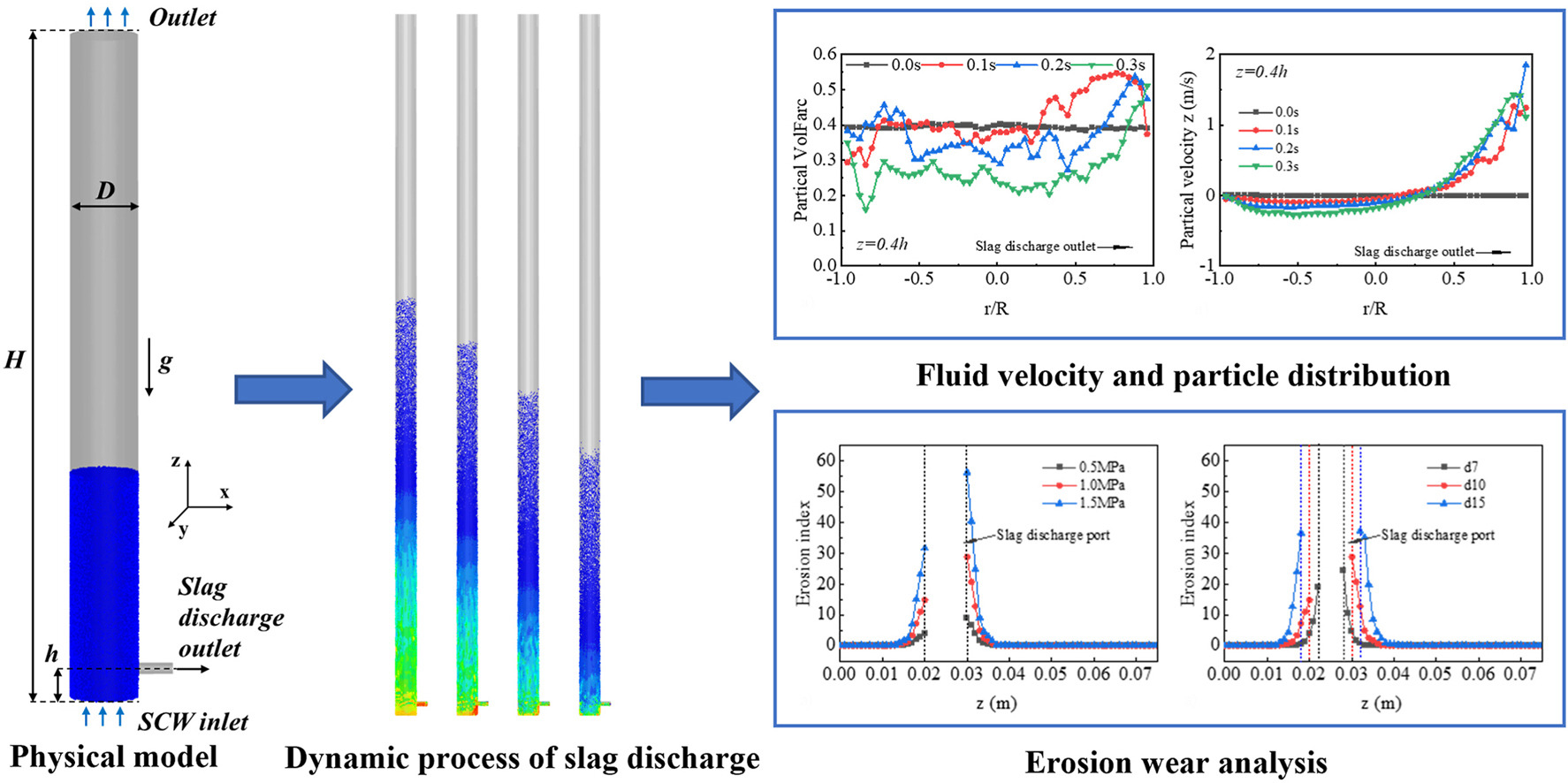

• A transient CPFD-based model was created to study slag discharge in a SCWG reactor.

• The hydrodynamic flow characteristics of particles were obtained.

• Interaction between particle motion and wall erosion is analyzed.

• The solid hold-up during slag discharge was over 90 %.

The simulation of the slag discharging process in supercritical water (SCW) fluidized beds is challenging due to the complexity of particle transport in a high-temperature and high-pressure environments. To balance computational efficiency with the need for detailed particle-level information, this study proposes a dynamic three-dimensional numerical model based on computational particle fluid dynamics (CPFD) to investigate the slag discharge process in a SCW fluidized bed reactor. This study presents the dynamic evolution of the flow field, velocity field, and particle phase volume fraction distribution during the slag discharge process, revealing the relationship between the uneven particle distribution and the flow field. Large particles are difficult to be discharged from the bottom of the reactor during the slag discharge process. By increasing the discharging time, the problem of dead zone at the bottom of the reactor can be alleviated effectively. Higher particle velocities and more frequent particle impacts cause more severe wear on the wall near the slag discharge outlet. Reducing the slag discharge differential pressure helps to reduce the wear of the connection. Throughout the entire slag discharge process, the solid holdup remains above 90 %, demonstrating the efficiency and rapidity of the slag discharge system. This work aims to provide valuable insights for the design and optimization of slag discharge systems.