- Volumes 108-119 (2025)

-

Volumes 96-107 (2025)

-

Volume 107

Pages 1-376 (December 2025)

-

Volume 106

Pages 1-336 (November 2025)

-

Volume 105

Pages 1-356 (October 2025)

-

Volume 104

Pages 1-332 (September 2025)

-

Volume 103

Pages 1-314 (August 2025)

-

Volume 102

Pages 1-276 (July 2025)

-

Volume 101

Pages 1-166 (June 2025)

-

Volume 100

Pages 1-256 (May 2025)

-

Volume 99

Pages 1-242 (April 2025)

-

Volume 98

Pages 1-288 (March 2025)

-

Volume 97

Pages 1-256 (February 2025)

-

Volume 96

Pages 1-340 (January 2025)

-

Volume 107

-

Volumes 84-95 (2024)

-

Volume 95

Pages 1-392 (December 2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 95

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

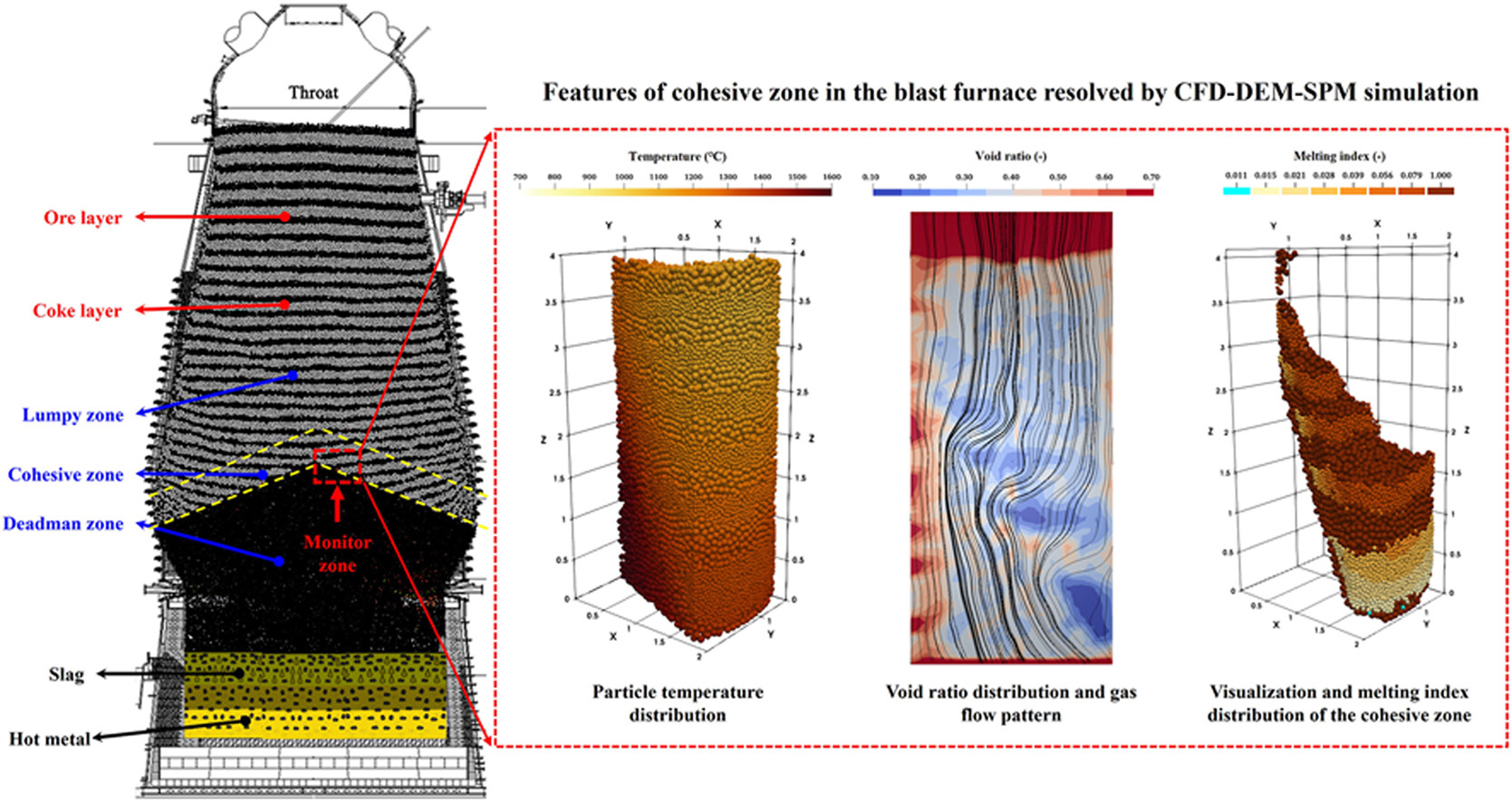

• A CFD-DEM-SPM has been established and validated.

• A softening particle model correlates Young's modulus with temperature.

• Cohesive zone characteristics and permeability degradation mechanisms are revealed.

• Effects of innovative low carbon BF technologies on the CZ are discussed.

To reduce greenhouse gas emissions in ironmaking, the steel industry is advancing innovative low-carbon blast furnace (BF) technologies. A critical challenge for implementing such innovations lies in optimizing permeability within the BF's cohesive zone (CZ), which directly impacts operational stability and efficiency. This study employs a coupled computational fluid dynamics-discrete element method (CFD-DEM) to calibrate Young's modulus by respectively fitting the relationship between Young's modulus and temperature, as well as pressure drop, based on a reported lab-scale softening and smelting experimental data of ore-coke heterogeneous alternating layer packed beds resembling BFs, and develops a softening particle model (SPM). The SPM establishes a temperature-dependent relationship between mechanical properties of softened ore particles and CZ conditions in industrial-scale BFs. Simulations of particle shrinkage behavior and pressure drop trends using the CFD-DEM-SPM framework demonstrate strong correlation with experimental data, validating its accuracy for predictive analysis. Furthermore, this study investigates how layer arrangement configurations, size ratios between ore and coke particles, and coke blending proportions influence CZ characteristics. Key findings identify an optimal batch weight configuration to enhance permeability within the CZ while maintaining operational stability. Additionally, results indicate that increasing the relative particle size of ore compared to coke or enhancing the proportion of blended coke in burden mixes improves CZ permeability, offering actionable strategies for reducing carbon intensity in BF operations. These insights provide critical guidance toward developing low-carbon BF processes compatible with global climate targets.