- Volumes 96-107 (2025)

-

Volumes 84-95 (2024)

-

Volume 95

Pages 1-392 (December 2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 95

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

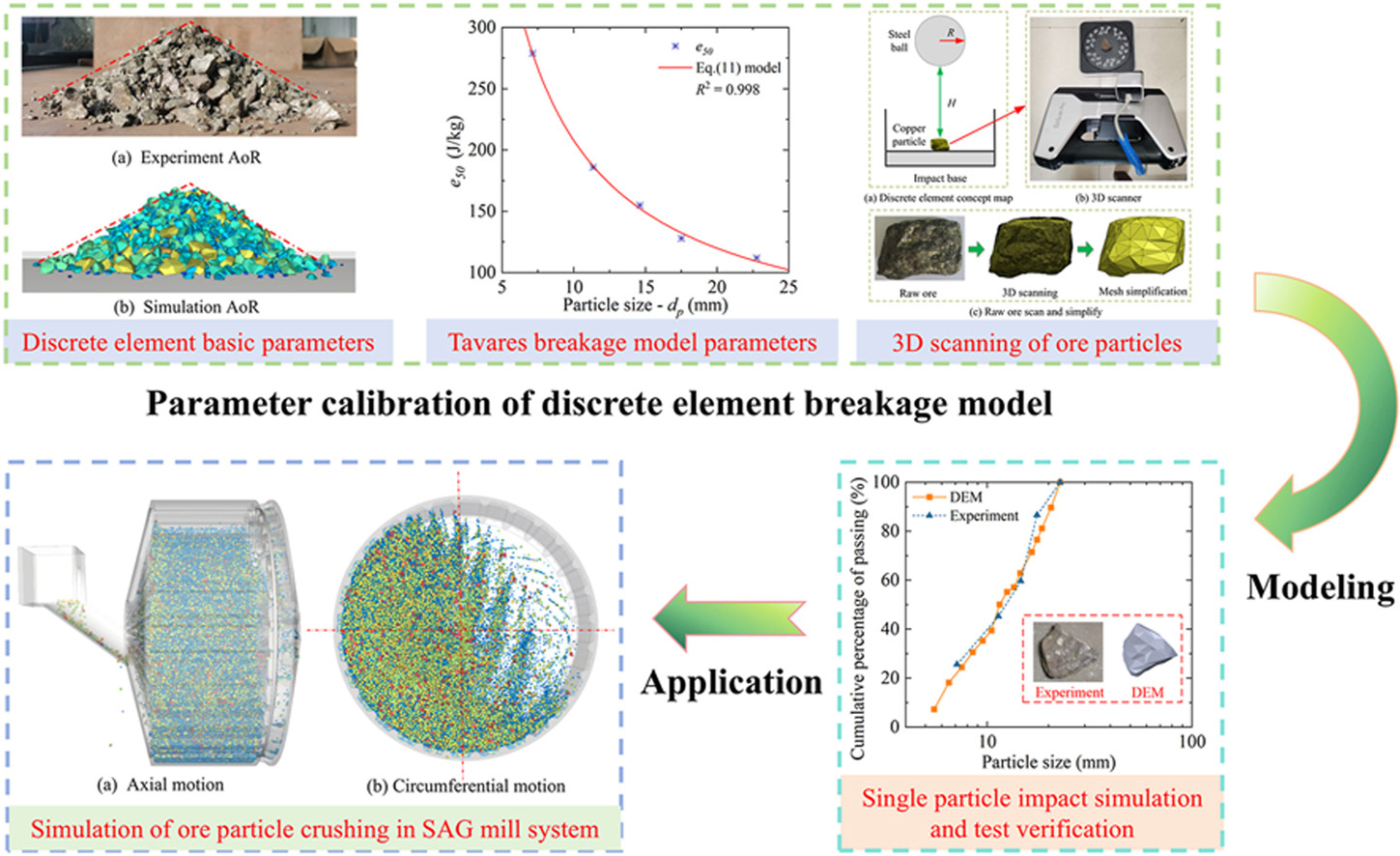

• Tavares breakage model parameters of ore particles are calibrated using single-particle impact tests.

• A detailed discrete element breakage model for ore particles is developed.

• Cumulative percentage of passing for particles crushing is used as validation index.

• Reliability of this parameter calibration method is preliminarily verified.

Accurately simulating the crushing process of ore particles in a semi-autogenous grinding mill (SAG mill) is quite challenging. This study utilizes the discrete element method (DEM) to construct a breakage model for ore particles. Calibration of the discrete element basic parameters and Tavares breakage model parameters is conducted based on angle of repose (AoR) tests and single-particle impact tests. 3D scanning is employed to capture the morphology of the ore for particle modeling. On this basis, a discrete element breakage model for ore particles is built for single-particle impact simulations and validated through testing to determine the calibrated model parameters. The results indicate that the AoR angles and stacking shapes from the simulation and tests are highly similar, with a relative error of about 0.19%. The similarity in crushing outcomes and quantitative values between single-particle impact simulations and tests preliminary validates the reliability of the calibration method and the applicability of the Tavares breakage model, successfully determining a group of model parameters suitable for simulating ore particle crushing processes. This study lays the groundwork for utilizing DEM to simulate the visualization of ore particle crushing.