- Volumes 96-107 (2025)

-

Volumes 84-95 (2024)

-

Volume 95

Pages 1-392 (December 2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 95

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

• The initial equilibrium droplet size distribution is d50 = 85–90 μm under V = 5 m/s at the separator.

• Examining the evolution of the equilibrium droplet size distribution from volume fraction of droplet population in detail.

• Providing a theoretical basis and support the strategy for the rational design of separation devices to promote droplet coalescence.

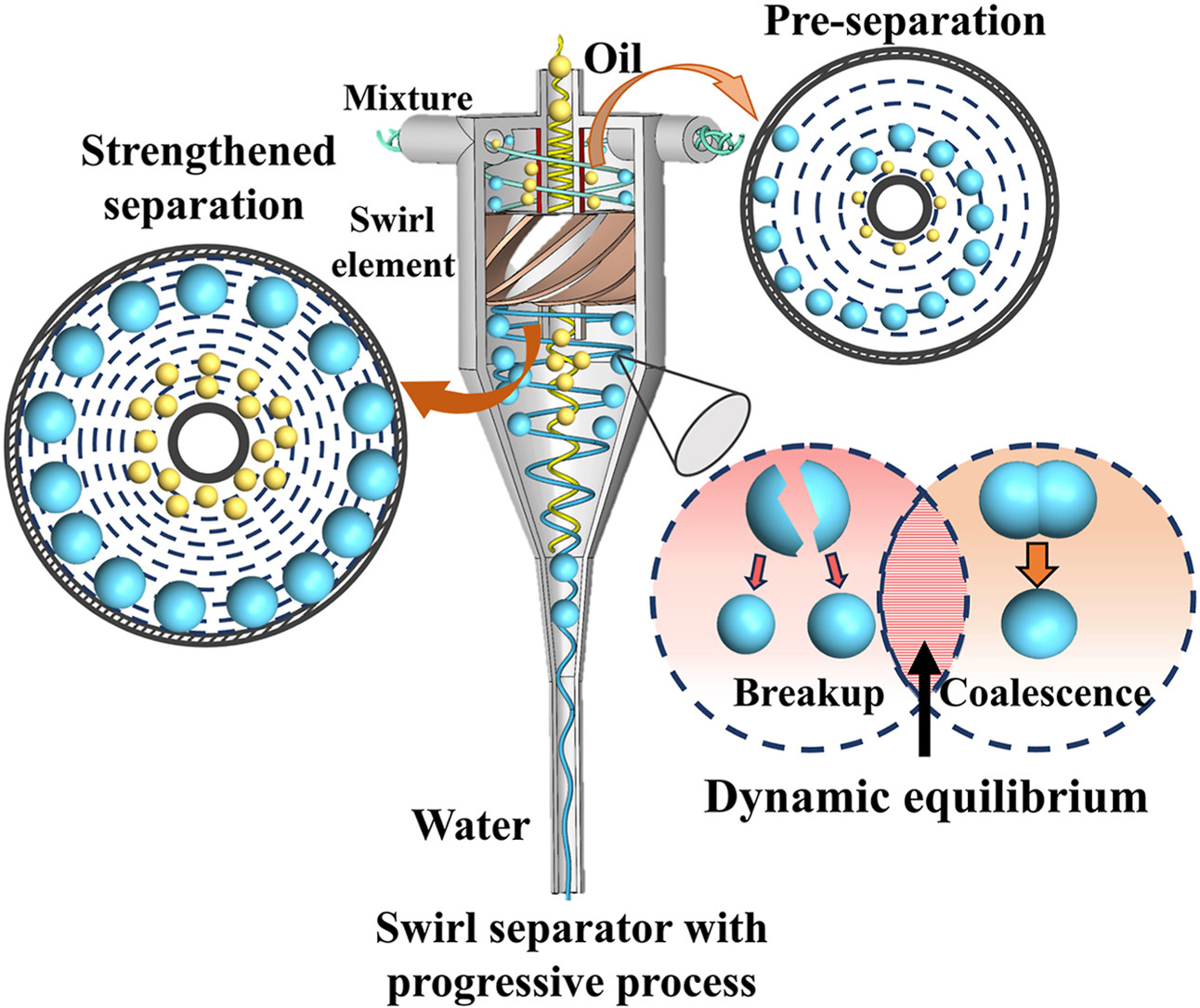

Tangential separator is widely used in industries as vital demulsification and dewatering separation devices but leads to high breakage rate of droplets. To address this, the swirl separator with progressive process was developed by exploiting operational merits of swirl element to minimize the breakage rate of droplet. The initial droplet size distribution has an influence on the droplet size distribution within the flow field. Accordingly, the droplet size distribution was analyzed numerically and verified through experimental measurements. The evolution of the droplet size distribution from the numerical simulation was then investigated. Based on these, the mechanism of droplet coalescence and breakup were examined. The results show that the initial equilibrium droplet size distribution is d50 = 85–90 μm at V = 5 m/s. Simultaneously, the turbulent dissipation rate is lower than the other initial droplet size distributions. Moreover, the numerical model can reasonably be utilized to the investigation. When the initial droplet size distribution is above d50 = 90 μm, the effect of droplet breakup is dominated. The rate of droplet breakup increases, and the coalescence rate decreases with the draining time of liquid film for coalescence increasing, which is unconducive to improve the separation efficiency. Conversely, if the initial droplet size distribution is below d50 = 85 μm, the swirl element promotes the droplet coalescence. The separation efficiency has an improvement. Additionally, the swirl element enhances the turbulent dissipation rate within the flow field.