- Volumes 96-107 (2025)

-

Volumes 84-95 (2024)

-

Volume 95

Pages 1-392 (December 2024)

-

Volume 94

Pages 1-400 (November 2024)

-

Volume 93

Pages 1-376 (October 2024)

-

Volume 92

Pages 1-316 (September 2024)

-

Volume 91

Pages 1-378 (August 2024)

-

Volume 90

Pages 1-580 (July 2024)

-

Volume 89

Pages 1-278 (June 2024)

-

Volume 88

Pages 1-350 (May 2024)

-

Volume 87

Pages 1-338 (April 2024)

-

Volume 86

Pages 1-312 (March 2024)

-

Volume 85

Pages 1-334 (February 2024)

-

Volume 84

Pages 1-308 (January 2024)

-

Volume 95

-

Volumes 72-83 (2023)

-

Volume 83

Pages 1-258 (December 2023)

-

Volume 82

Pages 1-204 (November 2023)

-

Volume 81

Pages 1-188 (October 2023)

-

Volume 80

Pages 1-202 (September 2023)

-

Volume 79

Pages 1-172 (August 2023)

-

Volume 78

Pages 1-146 (July 2023)

-

Volume 77

Pages 1-152 (June 2023)

-

Volume 76

Pages 1-176 (May 2023)

-

Volume 75

Pages 1-228 (April 2023)

-

Volume 74

Pages 1-200 (March 2023)

-

Volume 73

Pages 1-138 (February 2023)

-

Volume 72

Pages 1-144 (January 2023)

-

Volume 83

-

Volumes 60-71 (2022)

-

Volume 71

Pages 1-108 (December 2022)

-

Volume 70

Pages 1-106 (November 2022)

-

Volume 69

Pages 1-122 (October 2022)

-

Volume 68

Pages 1-124 (September 2022)

-

Volume 67

Pages 1-102 (August 2022)

-

Volume 66

Pages 1-112 (July 2022)

-

Volume 65

Pages 1-138 (June 2022)

-

Volume 64

Pages 1-186 (May 2022)

-

Volume 63

Pages 1-124 (April 2022)

-

Volume 62

Pages 1-104 (March 2022)

-

Volume 61

Pages 1-120 (February 2022)

-

Volume 60

Pages 1-124 (January 2022)

-

Volume 71

- Volumes 54-59 (2021)

- Volumes 48-53 (2020)

- Volumes 42-47 (2019)

- Volumes 36-41 (2018)

- Volumes 30-35 (2017)

- Volumes 24-29 (2016)

- Volumes 18-23 (2015)

- Volumes 12-17 (2014)

- Volume 11 (2013)

- Volume 10 (2012)

- Volume 9 (2011)

- Volume 8 (2010)

- Volume 7 (2009)

- Volume 6 (2008)

- Volume 5 (2007)

- Volume 4 (2006)

- Volume 3 (2005)

- Volume 2 (2004)

- Volume 1 (2003)

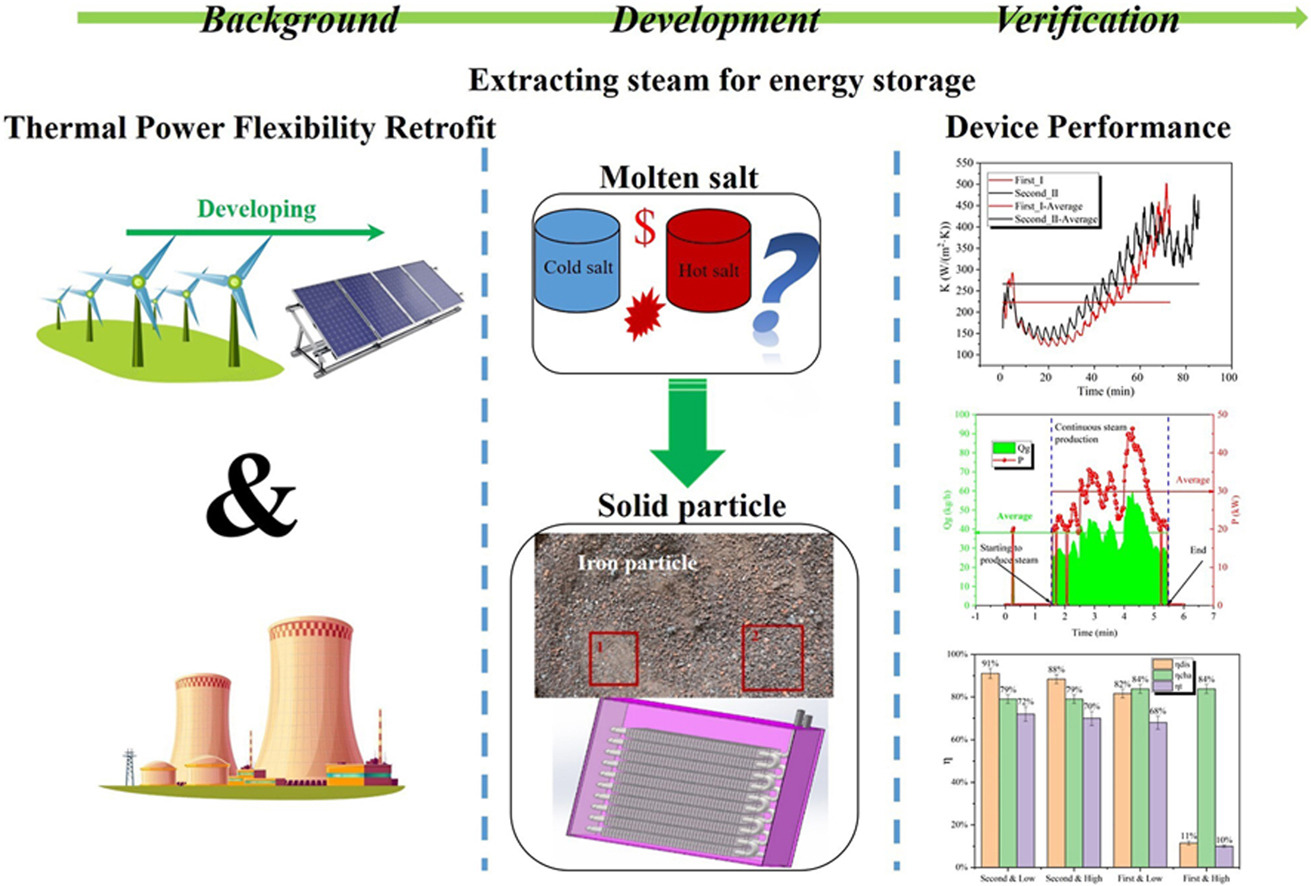

• Pilot-scale experimental device of steam-solid particles-steam was constructed.

• Mode II is superior with 13 kW charging power and 275 W/(m2 K) convective heat transfer coefficient.

• Mode II achieves 65% cycling efficiency, 79% charging and 82% discharging efficiency.

• Temperature difference map outlines preheating, evaporation, and superheating segments within the device.

Solid particles instead of molten salt as a heat storage medium for extracted steam energy storage are essential in thermal power flexibility retrofit. This study constructs a charge-discharge experimental device using by-products from the steel industry as heat storage materials, similar to a battery cell, which is easily scalable and accomplishes the steam-solid particle-steam energy conversion. Investigation parameters include temperature distribution, power variation, and cycle efficiency for different charging and discharging modes. Results indicate that the charging mode II outperforms mode I in temperature uniformity, charging flow rate, and pressure loss, yielding higher charging power and total convective heat transfer coefficients at 13 kW and 275 W/(m2 K), respectively. The pilot device demonstrates commendable insulating properties. Its heat dissipation rate is approximately 33.33%, which surpasses that of reported thermal storage devices. Moreover, the mode II exhibits superior temperature non-uniformity during heat release, ensuring that 40 kg/h of superheated steam at 220 °C can be produced continuously for 5 min. The cycling efficiency is noteworthy, reaching 65% in low flow rate discharge, accompanied by 79% charging efficiency and 82% discharging efficiency. A temperature difference cloud map elucidates the primary phase change region, emphasizing preheating, evaporation, and superheating segments. Experimental results provide new ideas for combining waste elimination in the steel industry and energy storage in thermal power plants.