• Four TiO2 with different crystal structures, particle shapes and surface coatings investigated.

• Inter-laboratory comparison of specific surface-area, density and size distribution.

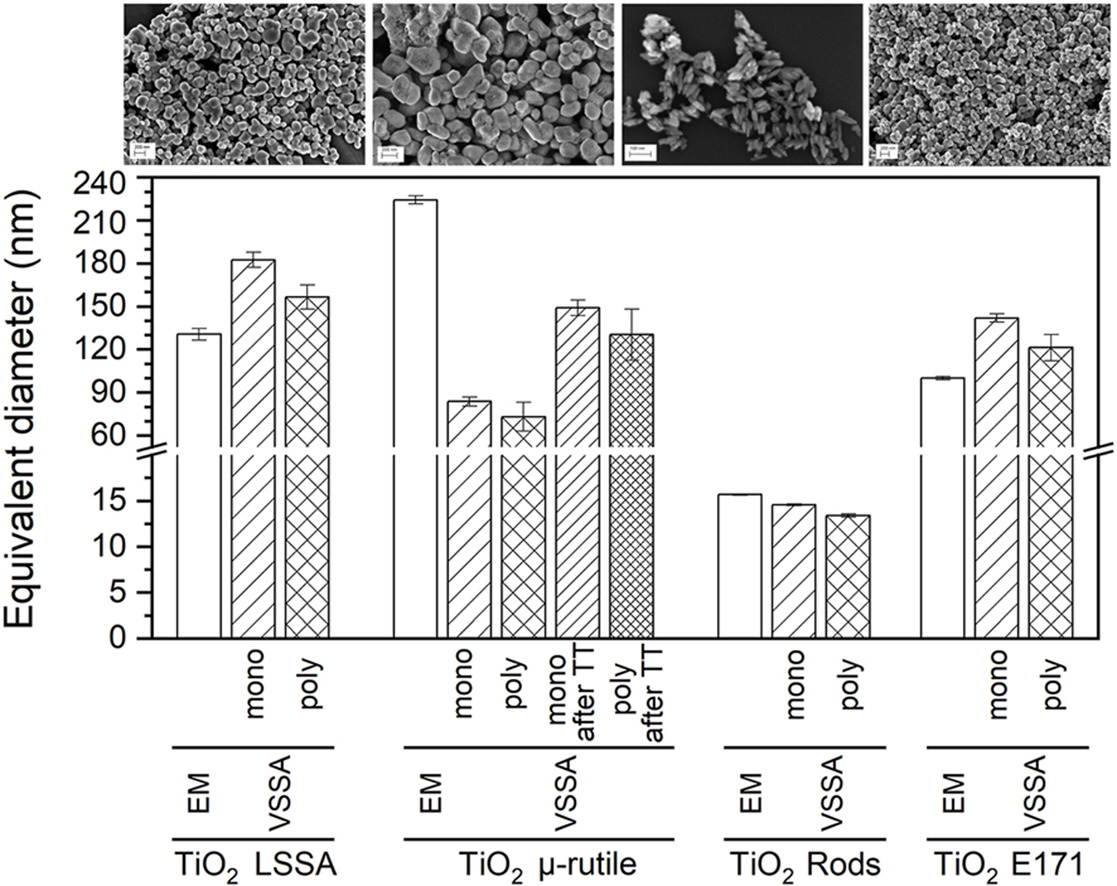

• Constituent particle diameter determined from volume specific surface area (VSSA) accounting for polydispersion.

• Particle diameters obtained from VSSA and EM measurements within ±20%.

In this work, four samples of TiO2 powder materials with different structures (rutile, anatase), surface coatings and morphologies (rod, pseudo-spherical) were characterized by four partners involving complementary methods. With the aim of producing inter-laboratory reproducibility data, the specific surface-area, bulk density, and number size distribution were measured, yielding a satisfying agreement between partners. The equivalent diameter of constituent particles was determined from the sample volume specific surface area (VSSA) – accounting for polydispersion – and compared to electron microscopy (EM). Constituent particle diameters ranged from 15 to 225 nm according to EM analyses. The relative discrepancies between VSSA-based and EM-based diameters were found within ±20%. Out of the four samples under study, TiO2 μ-rutile leads to a larger deviation, which was attributed to surface coating thanks to complementary analysis. Assuming that the sample is pure, an equivalent diameter based on the VSSA can be determined, provided that the shape of constituent particles is known or supposed.