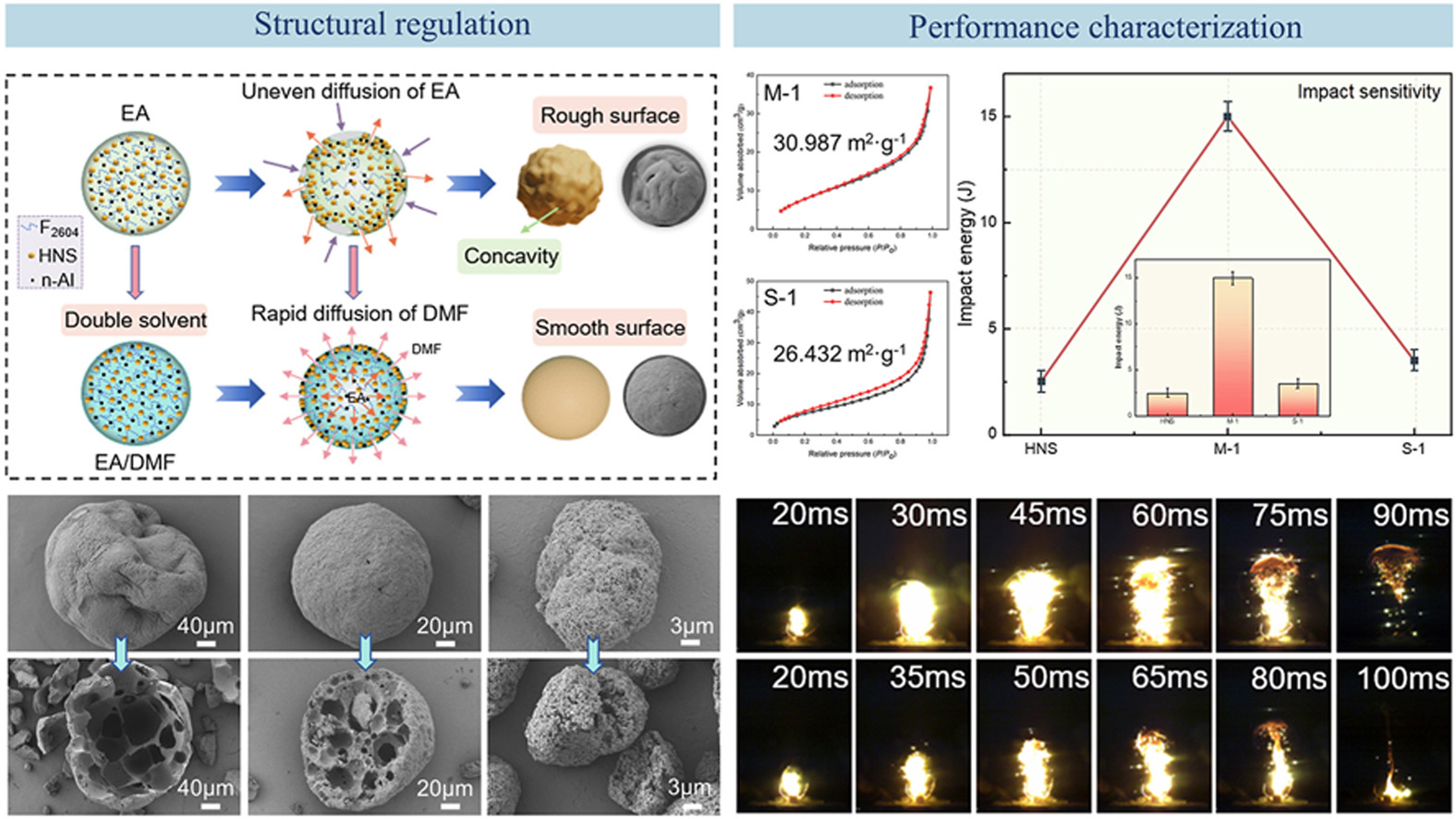

• HNS/n-Al microspheres with interconnected multi-cavity structure were prepared.

• Multi-cavity structure enhances the safety performance of Aluminized explosive.

• The n-Al inhibits the formation of large carbon clusters during the combustion process.

• Multi-cavity structure enhances the combustion efficiency of HNS.

Achieving performance optimization of aluminized explosives through structural regulation is of great significance for enhancing their practical application value. In this study, hexanitrostilbene/aluminum (HNS/Al) microspheres with interconnected multi-cavity structures were prepared using microjet droplet technology, and the effect of solvent ratio on microsphere morphology and multi-cavity formation was investigated. Furthermore, the impact of the multi-cavity structure on microsphere dispersibility, specific surface area, thermal properties, mechanical sensitivity, and combustion performance was examined. The results indicate that, compared to raw HNS, the multi-cavity HNS/Al microspheres exhibit improved dispersibility while retaining the crystal structure, chemical composition, and thermal stability of the raw material. In comparison to solid HNS/Al microspheres, the multi-cavity HNS/Al microspheres demonstrate a higher specific surface area (26.432 vs. 30.987 m2 g−1) and improved safety performance (3.5 vs. 15 J). Ignition test results reveal that the addition of aluminum powder significantly reduces the ignition delay of HNS (275 vs. 5.0 ms) and inhibits carbon cluster formation during combustion, thereby enhancing the burning efficiency of HNS. Notably, microspheres with a multi-cavity structure exhibit superior combustion efficiency. This study provides a method for preparing multi-structured aluminized explosives.