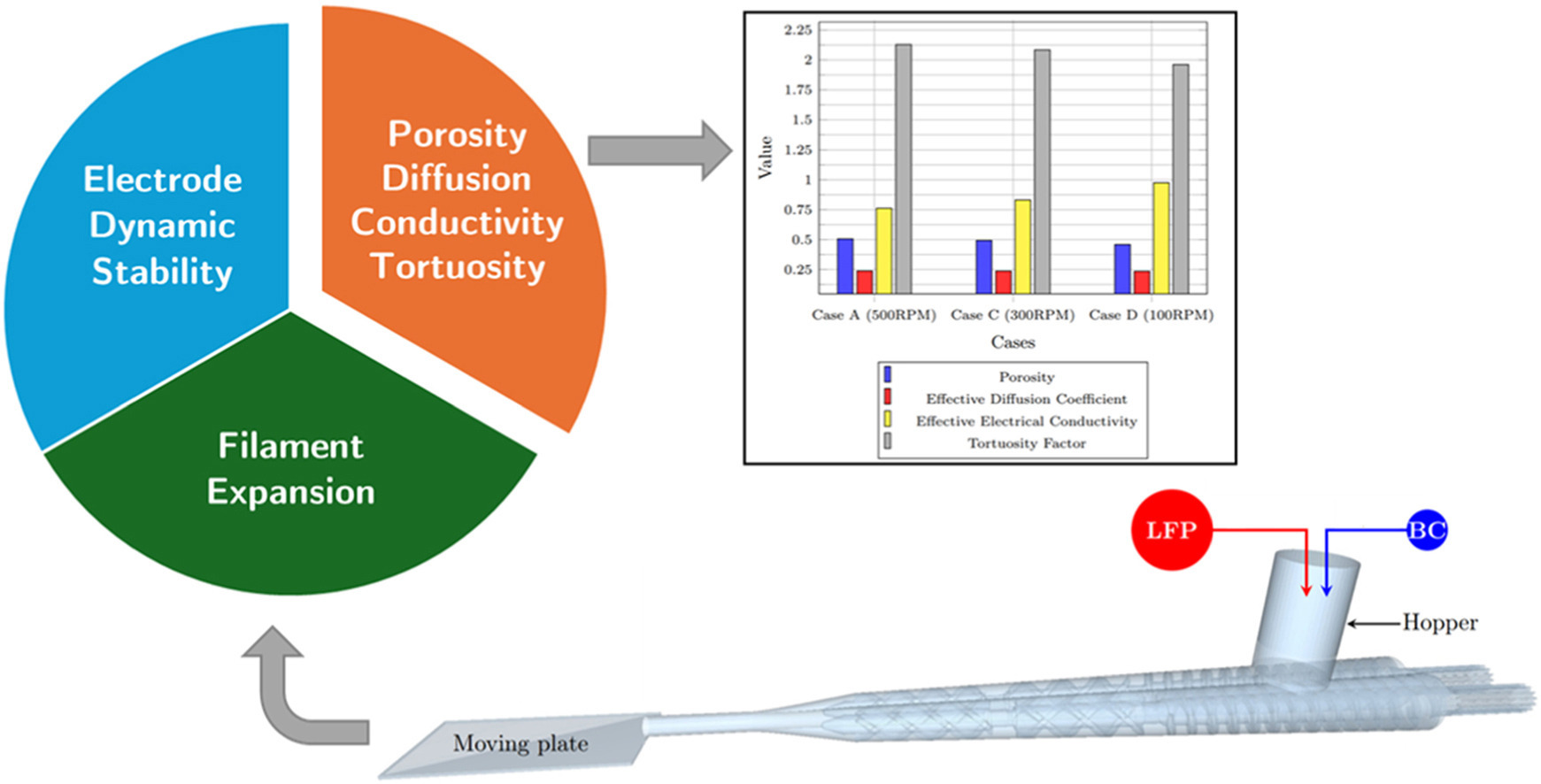

• DEM simulation of solvent-free (dry) electrode manufacturing.

• Investigation of process conditions on battery filament fabrication.

• Analysing pore-scale properties of filaments.

Material extrusion is a key step in the solvent-free fabrication of lithium-ion battery (LIB) electrodes, offering reduced costs and environmental impact compared to slurry-based methods. While discrete element method (DEM) based mesoscopic models have been used to study twin-screw extrusion, the microstructural characterisation of extrudates immediately after nozzle exit remains unexplored. In this study, a series of DEM simulations were conducted to perform a sensitivity analysis of the microstructure and electrochemical performance-related parameters of extruded electrode filaments by varying the feeding rate and feeding mode, screw rotational speed, and particle cohesion. Furthermore, this work addresses the previously unexamined phenomenon of filament expansion during extrusion. By introducing the Augmented Dickey-Fuller (ADF) method, the study also provides the first analysis of the temporal dynamic stability of filament quality during the dry electrode manufacturing extrusion process. The results show that increasing the screw speed from 100 to 500 RPM reduces porosity by 10 % and limits expansion, while lower speeds improve consistency in electrode quality. A novel approach to quantifying dynamic behaviour is proposed, offering insights for optimising solvent-free electrode manufacturing.