• CFD-DEM model for SC-CO2-carrying particles is developed.

• The variation rule of SC-CO2 flow field in the fracture is investigated.

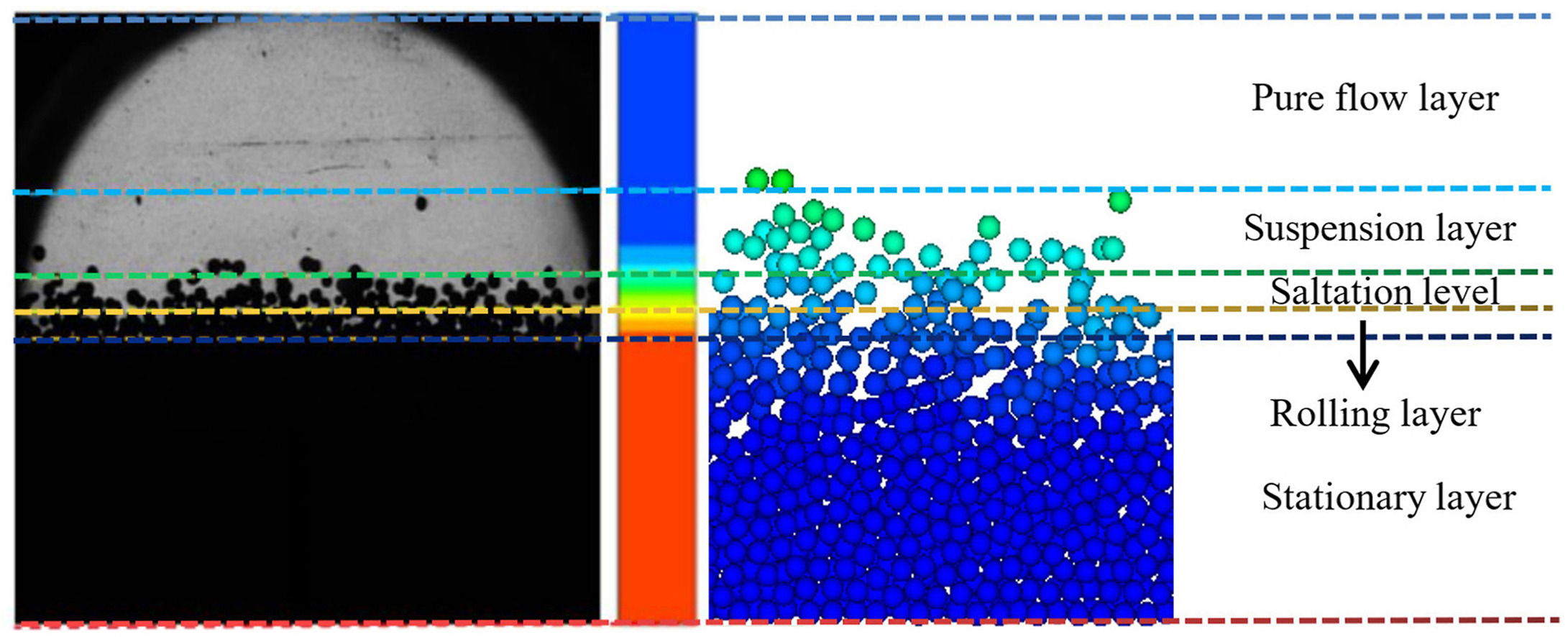

• The distribution pattern of particles in the SC-CO2 fracture is analyzed.

• The model provides a good technical support for SC-CO2 fracturing in deep wells.

In this study, a coupled CFD–DEM framework incorporating heat transfer was established to elucidate the transport and deposition behavior of proppant particles in supercritical CO2 (SC-CO2) fracturing. A three-dimensional fracture-scale physical model was developed to investigate the effects of particle concentration, density, diameter, and non-sphericity on the evolution of the proppant bed. The simulations reveal that both the equilibrium height and length of the granular bed increase with particle concentration, exhibiting a near-linear dependence on the injected mass flux. As particle density rises, the bed height increases while the deposition front advances upstream, facilitating earlier bed formation. Increasing particle diameter from 0.4 mm to 1 mm produces pronounced morphological changes—larger particles form thicker, shorter beds, whereas smaller particles are more easily transported to distal fracture regions. Enhanced particle non-sphericity promotes the development of higher and wider beds due to increased mechanical interlocking and larger inter-particle voids, which strengthen flow-channel connectivity and potentially improve hydrocarbon recovery. The integrated thermal–hydrodynamic–granular analysis demonstrates that SC-CO2's temperature-dependent viscosity and density variations significantly modulate drag, lift, and buoyancy forces, jointly governing the self-organization and stability of proppant beds within fractures.