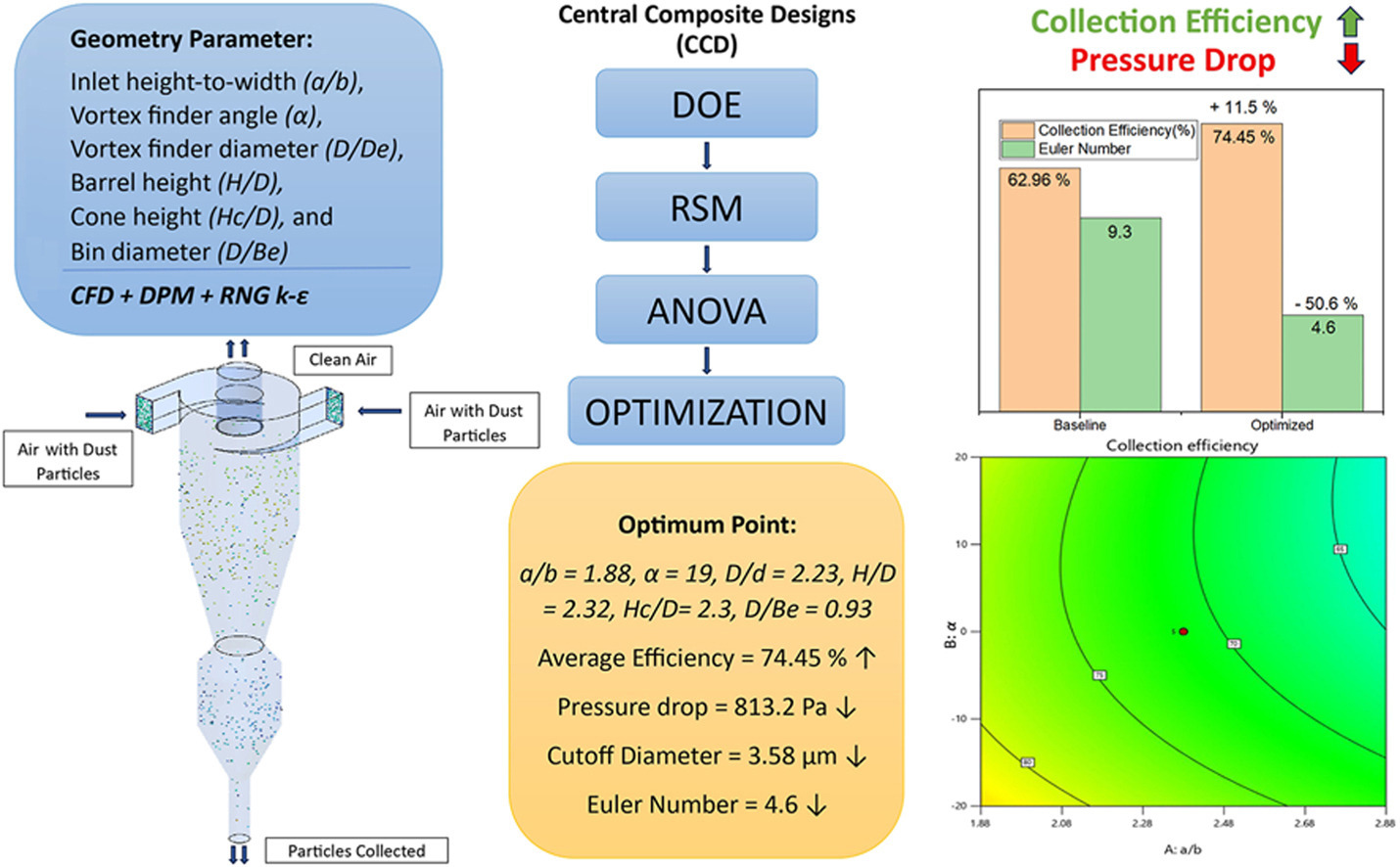

• Dual inlet cyclone separator optimised using CFD and response surface methodology.

• Six key geometric parameters analysed for efficiency and pressure drop effects.

• Optimised design improves collection efficiency by 11.5 % and cuts pressure drop.

• Euler number reduced by 50.96 %, cutoff diameter lowered by 16.15 %.

• Statistical model validated with CFD, prediction errors within acceptable range.

Given the growing emphasis on sustainable industrial practices and regulatory constraints on particulate emissions, enhancing cyclone separator performance remains a critical area of research for ensuring the high-efficient solid-gas separation with minimal energy penalties. This study presents a comprehensive numerical investigation and multi-objective optimisation of a dual-inlet cyclone separator to enhance the particle collection efficiency while minimizing the pressure drop. The Eulerian-Lagrangian approach is employed using the RNG k – ε turbulence modelling, coupled with the Discrete Phase Model for particle tracking. Key geometric parameters, including the inlet height to width, vortex finder angle, vortex finder diameter, barrel height, cone height, and bin diameter, are systematically varied to analyse their effects on the cyclone performance. Two optimal factors are tested among the three most significant factors at once to evaluate their combined effects on the collection efficiency and the pressure drop. Results indicate that the optimised cyclone design improves average collection efficiency by 11.5 % across particle sizes, reduces the Euler number by 50.96 %, and lowers the particle cut-off diameter by 16.15 %, while maintaining a balanced trade-off with the pressure drop. The prediction errors for the pressure drop and the collection efficiency are within acceptable limits at 11 % and 3.5 %, respectively. The improved geometry strengthens the tangential flow and moderates the peak axial velocity, resulting in a more effective centrifugal separation for fine particles.